Description

Polyethylene plastics are widely used in manufacturing, packaging, and industrial applications due to their durability, chemical resistance, and recyclability. Here’s how they differ:

HDPE (High-Density Polyethylene)

Rigid & Strong – High tensile strength, making it ideal for pipes, containers, and industrial applications.

Chemical & Moisture Resistant – Used in milk bottles, detergent containers, and fuel tanks.

Recyclable & Eco-Friendly – Often repurposed into new plastic products.

LDPE (Low-Density Polyethylene)

Flexible & Lightweight – Commonly used in plastic bags, shrink films, and food packaging.

Soft & Transparent – Ideal for squeezable bottles and flexible packaging.

Resistant to Impact & Moisture – Used in agricultural films and insulation materials.

LLDPE (Linear Low-Density Polyethylene)

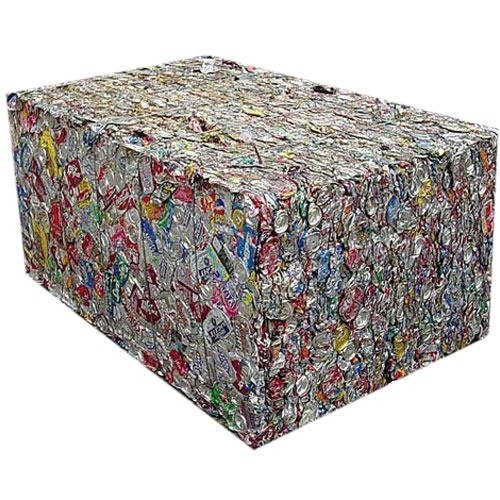

Tough & Puncture-Resistant – Used in stretch wrap films, heavy-duty bags, and liners.

More Flexible Than LDPE – Offers better tear resistance while maintaining flexibility.

Ideal for Extreme Conditions – Used in industrial packaging and protective covers.

Reviews

There are no reviews yet.